|

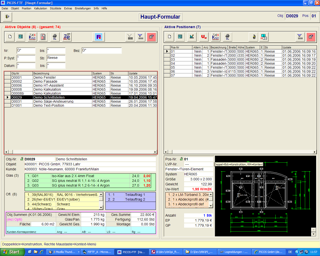

Project Processing, Input

|

Project Processing

When you start PICOS-FTF, a list of all recorded projects is displayed.

Your most recent project is already active, so you do not have to search for it.

From here you start the project processing as well as the project calculation and the generation of all disposition and production documents, i.e. project parts lists, cutting optimization and export of requirement and production data.

|

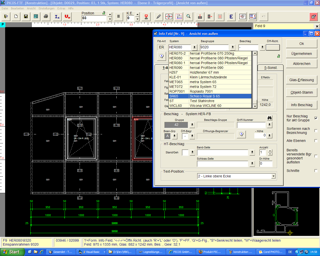

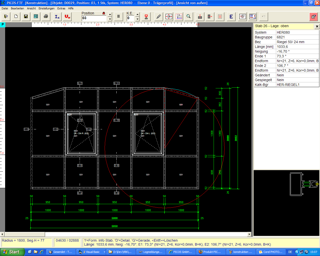

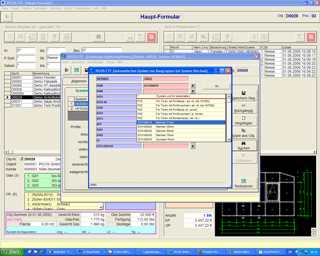

Construction

PICOS-FTF allows you to get information about the active drawing element and to change it by using the right mouse button, i.e. profile data with detailed view, end forms and deviations. All field contents and fittings are processed in the same way.

Panes and panels are shown with dimensions respectively model panes and corresponding glazing information.

You can use the "drag and drop" functions for a faster processing.

|

Construction, Bar Properties

|

|

Mixing Profile Systems

|

Mixing Profile Systems

With PICOS-FTF you can mix profile series within one project. Do you have to manufacture windows with profile system X and doors with profile system Y for instance? Or would you like to integrate any wing into your facade? You just give the respective specification and receive detailed order documents sorted according to the profile systems used.

|

Calculation

With PICOS-FTF you can make any change directly within the live elevation on the screen, i.e. changing the endpoint of a circular arc, displacement of profiles, axes and points.

Subsequently, PICOS-FTF calculates the changed element features in real time.

Input errors are reported right away so that you can react accordingly.

Dimensions are generated automatically, measurements of axis and span dimensions as well as profile widths are shown optionally.

|

Construction, Rounding

|

|

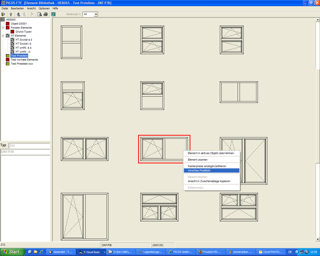

Library of Window and Door Elements

|

Library of Window and Door Elements

Frequently used elements are stored in libraries. This enables a very fast creation of your new elements! The well structured graphical library can be changed and extended any time.

After copying a stored type into your project, you can not only change the measurements, you can even change the construction. For instance a transom can be added or removed, slants or curves can be added, a door with one wing can be changed into one with two wings. Your advantage: you don´t have to start all over with your element if there are changes to be made.

|

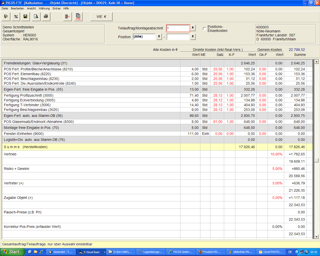

Project Calculation

PICOS-FTF offers you a complete, exact and extremely flexible calculation for your offer management.

Material, production, mounting and overhead costs can be assigned in any desired report.

Each cost group can be modified individually by factors and rates.

General surcharges and discounts such as sales, risk and profit, complete the calculation sheet.

|

Summary of Project Costs

|

|

Alternative Calculation

|

Alternative Calculation

PICOS-FTF implements the calculation of your project in an alternative profile system - without the need for making manual modifications in each item!

This way you can find out which profile system allows you to submit the most economical offer.

|

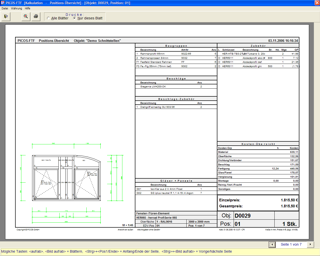

Calculation Reports

PICOS-FTF provides a wide variety of evaluation and output possibilities.

In addition to a summary of project costs, you get various lists related to the different items.

The combination of detailed cost blocks with a graphical elevation gives you a maximum of information.

To represent your company attractively, data of your project positions are combined with formatted text modules for your customer correspondence such as offers, order confirmations, delivery notes etc.

|

Graphical Summary of an Item

|

|

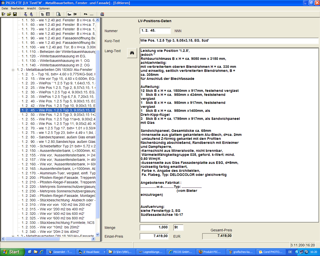

Editing the Bill of Quantities

|

Bill of Quantities

With PICOS-FTF you import data from bills of quantities (GAEB-format) from architects or property developers into your offer processing.

This saves a lot of time entering large quantities of data. Reversely, files can be automatically produced from PICOS-FTF for the bill of quanties.

The costs information which is stored in the data base is available for external access of third parties.

|

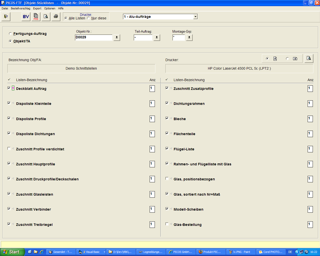

Project Parts Lists

According to utilization, disposition and production lists are arbitrarily arranged with PICOS-FTF.

Individual or multiple lists can be displayed or printed.

You can also use these lists as order forms, e.g. for material or for external labour.

The possibility of batch processing is an enormous time saver for your routine tasks.

|

Configuration of Parts Lists Configuration of Parts Lists

|

|

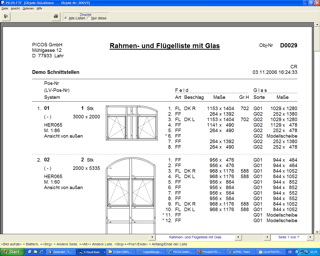

List Frames and Wings

|

Manufacturing and Assembly Lists

PICOS-FTF offers you a lot of prebuild list and label types for profile processing, of course with integrated cutting optimization.

Frames and wings of your production orders are concisely listed with graphical element representation.

Information on mounting of fittings and glass is additionally contained on these lists.

This way, search processes during assembly and mounting are avoided.

|

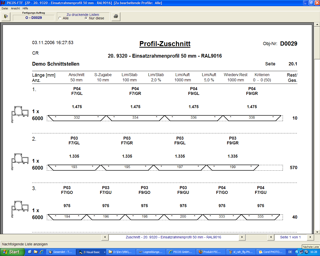

Interfaces

PICOS-FTF sorts all lists according to disposition groups. Consequently you can provide exact and specific parts lists to each production point.

Based on the cutting optimization, a control file for your profile processing machines is generated.

An online connection to a control system can be integrated as well.

All data of the project parts lists can be passed on to external systems, e.g. stock management or ERP.

|

Result of the Cutting Optimization

|